Construction and commissioning of malting plant

Have you ever thought about building a malting plant? Maybe many investors who aim to invest in malting plants ask themselves this question: to convert a grain of malting barley to barley malt, it is first soaked so that it germinates, and, then it is dried. So the process of malting barley is simple. Then why do we need to look for a brewmaster for building a malting plant?

You are not the only person thinking about this. From your perspective, there might not be a challenge. However, we must tell you that building a malting plant is more complicated than building plants for other beverages you might have thought about.

Let us explain ourselves. You should know that more than 40 types of malt are produces nowadays, and each of these types is produced with a different method. The plant that you are thinking about and plan to produce malt in will be able to produce only 5 barley malt products.

Now, ask yourself how many of these malt types you know or how many methods of barley malt production you are familiar with.

With malting experts and brewmasters trained at the University of Munich, Avina Technology Group ensures you that investing in this industry is not only attractive and profitable compared to other industries but also provides you with up-to-date European and international malting technology, and you can move toward a knowledge-based barley malt product.

Production of standard barley malt:

Barley malt is recognized internationally through certain indicators and standards. Obtaining these standards, the barley malt must go be subjected to necessary experiments in advanced laboratories so that adequate barley malt can be prepared. Adequate barley malt here refers to that used for brewery. These types of malts are usually certified by the MEBAK standard around the world. We are able to conduct these experiments according to the same international standards. (For further information, refer to the page Malting barley research and development.)

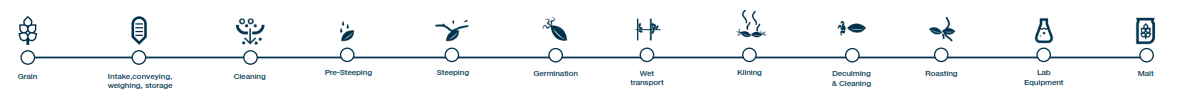

Malt production process

As you might already know, the main goal of Avina Technology Group is making it possible to produce malt according to international quality and standards. To realize this goal, we need a modern malting plant to produce high-quality and standard malt. We have offers for constructing malting plants of any size. One of our offers for low-to-medium capacity is the Schulz malting system.

Schulz malting system, from low to medium size

To prepare suitable ingredients for your modern malting plant, you can refer to Avina Agricultural Group.

Now, if this sections has motivated you to invest and be active in the malting industry, seize the opportunity and contact us. Avina Technology Group can be on your side and provide services as a technical consultant in all the stages of constructing and commissioning the malting plant in the best way possible and using the knowledge and expertise we have gained and the offers we have for constructing and commissioning malting plants with various capacities.