Integrated design and engineering of beverage plants

Integrated design and engineering of beverage plants for producing new products.

To produce a successful beverage in your plant, the best option is proficient and integrated design and engineering that consider all the required international standards. Avina Technology Group will assist you as a specialist consultant with its expertise and experience in the international beverage industry and according to the stage your project is at or how large it is.

You know that the integrated design and engineering of a beverage plant for a new product will accelerate your progress toward success.

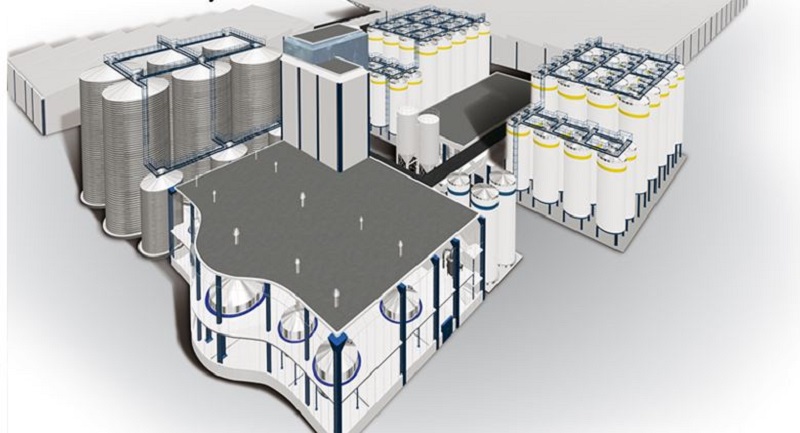

Master Planning

Good design is half of the path to success. All the processes, workflows and activities exist in the design and planning. Steps such as the receipt and sending of ingredients, production, transport of bottles and packaged product, and product warehousing are considered in the comprehensive plant design.

The main plant design has several implementation phases, all of which are planned in the Engineering Department with the consideration of production lines with different production processes and their capacities. Implementing the production processes can be completed step by step in the subsequent phases to complete your product portfolio.

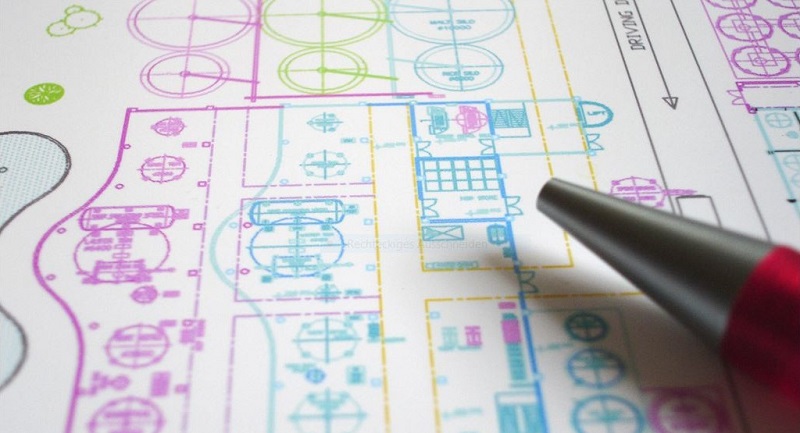

Layout Planning

With their sufficient knowledge and experience in the production of beverages and considering all the standards for producing various non-alcoholic beers, juices, dairy-based drinks, etc., our engineers design your plant with working drawings.

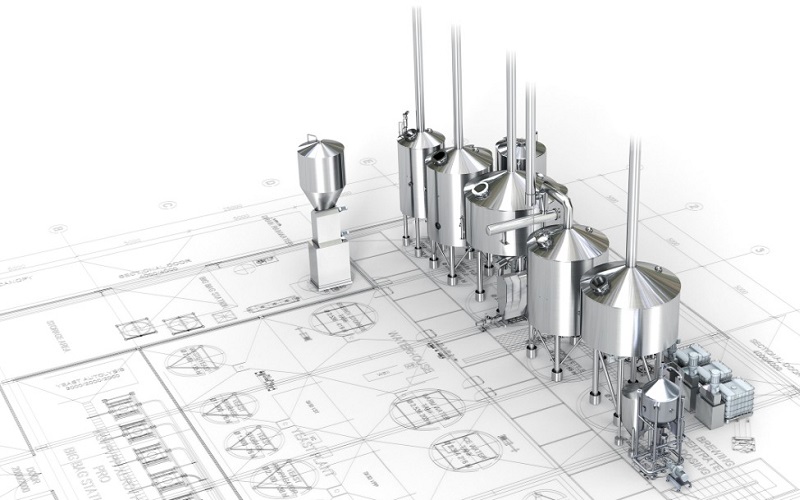

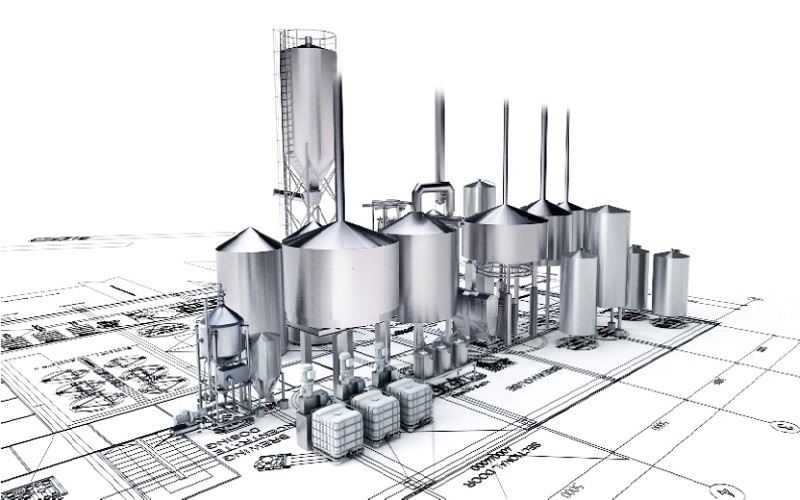

The following images show a sample design and engineering project for a SABMiler plant. This project has been designed in different phases by our experts and has been implemented to increase the production capacity of the subsequent phases. Moreover, all the phases have been taken into consideration in the initial design.

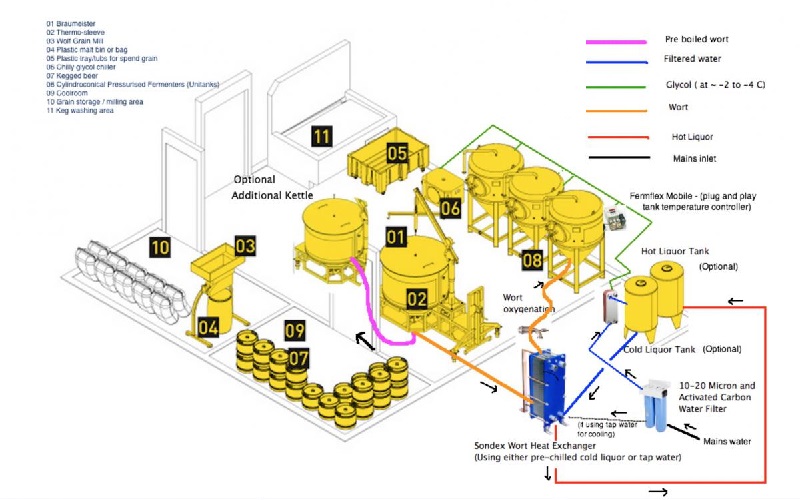

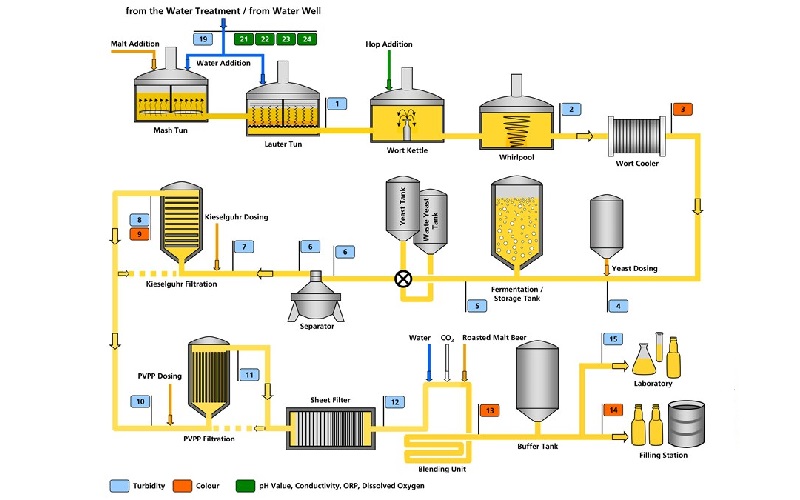

Detailed Process Design

The key points of a project are in its details. [ Now, all the components and equipment must be installed at correct locations, and every pipe must be correctly calculated. In addition, many parts must be designed independently of performance. Every silo, vessel, and process element is designed and planned according to the requirements of the customer. The vessels and piping are designed with professional software, while the economy of the plant is the constant focus.

Our engineers make sure that this process is carried out optimally and is designed and engineered for our customers considering the beverage quality, production method and process, and required technology from the beginning of production up to where the product reaches the customer according to the required investment.

Plant design and architecture

Beverage production plants have production halls, brewhouses or syrup rooms, treatment, ingredients and product warehouses, office buildings, and other spaces, which are very similar to each other. However, detailed design and engineering and knowledge and arrangement of apparatus and machines, the input and output capacities of each part, and the processes and workflows before constructing the plant will save you from future reworks. Avina Technology Group accompanies you in this path and offers you a complete package including full design and engineering of the beverage production plant.