A new generation of ZHEUPACK hot melt adhesive labeling machine

The design philosophy of the new generation ZHEUPACK hot melt adhesive labeling machine is: safety, high efficiency, cleanliness, environmental protection, barrier-free operation, easy maintenance, low accidents, accuracy, high speed and stability.

Application of new technology of electronic intelligence

Sino-German RFL-series hot melt adhesive labeling machine adopts brand-new intelligent technology through the electric control system, which eliminates most of the mechanical transmission system: gears, chains, synchronous drive belts and mechanical connecting parts. Compared with the traditional hot melt adhesive labeling machine, the new design concept shows obvious advantages: there is no wear of the gap between the mechanical meshing teeth, which improves the labeling accuracy and stability of the labeling machine. Due to the reduction of mechanical transmission components, the maintenance cost is reduced (maintenance cost is saved by more than half). The key components on the surface of the standard machine table are all within the scope of visual control. There is no need for any routine inspections due to the lack of mechanical transmission components under the table top

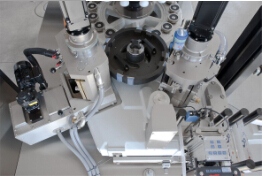

Cut label heart-cut label drum

The supporting shaft of the rotary marking cutter is a silicon aluminum alloy casting. The material of the overall external support structure is also made of silicon-aluminum alloy. This design solves the problem of thermal expansion coefficient differences due to temperature gradients. The supporting shaft of the cutting label is designed by the finite element method, and the cutting knife maintains a good balance during the high-speed rotation. Guaranteed accurate label cutting efficiency. Even if the temperature increases, the marking knife is still sharp and does not wear out. In addition, the structure is simple and convenient for operation and adjustment. Compared with traditional label cutting, the new label cutting technology can guarantee 200 million times of label cutting without changing the label cutting knife.

Servo-motor-driven double labeling plate – automatic labeling system

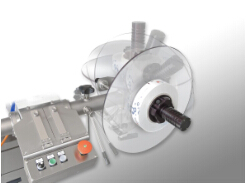

The two dials are equipped with two independent servo drive motors. In order to reduce costs, customers continue to choose thinner, smaller and narrower label materials. This change in the selection of materials requires extremely precise control of the tension of the marking paper. In today’s technological advancement, the marking plate driven by the servo motor is the key technology to ensure the tension of the marking paper. Different from the traditional way of releasing labels, the tensioning and tightening of the label plate adopts pushing force instead of pulling force, which prevents the machine from stopping due to excessive stretching of label paper and stress. The new hot melt adhesive labeling machine has a wider range of applications for the selection of labeling paper materials. Automatic bid receiving system: Program automatic control, no need to stop, automatic bid receiving.

Vertical Superscript – Hercules – Juli Helper

Vertical Superscript – Hercules – Juli Helper is the Vertical Superscript Hercules system is RFL Hot Melt Adhesive Technology. This technology eliminates the trouble of using lifting equipment, and easily places the label on the label support. The advantage of this system is the reduction of lifting equipment. Usually, the weight of the label exceeds the weight limit stipulated by the safe operation regulations. In addition, the common problem is that it is often difficult to effectively grasp the breakthrough with a narrow target. Lifting the reel past the reel support columns is very difficult. The most prominent problem is: the operator tries to grasp the outer edge of the label roll when installing the label roll. Since the label paper is too narrow and the reel label roll is relatively unstable, the label paper is easy to collapse, causing the entire roll of label paper to collapse. scrapped. Hercules – Juli helper superscripting system avoids the collapse of narrow label rolls. Comes with standard mobile tray. When the mobile cart of the label comes out of the warehouse, the label has been placed vertically on the mobile cart. The operation is safe, simple and convenient, eliminating the need for lifting equipment. The labeling machine is equipped with a special transmission tray (Zhongde can provide tool kits according to customer needs) to send the car loaded with label paper from the warehouse to the label machine, and install the label paper vertically.

Pollution-free, environment-friendly glue supply system

Glue supply system:

The glue supply system of the labeling machine is the key to keep the labeling machine clean and environmentally friendly. The new sol system is a special glue dispenser designed and developed by scientific researchers through a large number of analysis and research through high-speed cameras. No “steam and fumes” are produced during the labeling process. The production environment is clean and comfortable.

a. Advanced glue filtration system. The system filters the pods through the glue and returns the glue through a dedicated drain hole. The fragments of label paper in the backflow glue are isolated in the separation cabin, so that the backflow glue is clean and environmentally friendly.

b. Glue box for easy maintenance and cleaning. The rubber box is installed directly under the rubber supply roller. The structure is different from the traditional labeling machine, the rubber box can be detached without removing the rubber roller, which is convenient for maintenance and cleaning. Reduce maintenance costs.

c. Under the pneumatic drive, the rubber box and rubber roller can slide horizontally. Or under the drive of the servo motor, translate rapidly. And the clutch can be activated during high-speed operation. (No bottle/no label paper system) Adjust the inclination angle of the rubber roller through the fine-tuning screw to ensure the precise, stable and uniform contact between the rubber roller and the rubber pad on the label cutting vacuum drum. Due to the uniform pressure of the rubber roller on the elastic pad, it is ensured that the glue is perfectly distributed on the surface of the label paper adsorbed on the pad. This uniform pressure avoids the wear of the rubber pad due to uneven friction. In the traditional adjustment system, the rubber roller is constantly subjected to the mechanical stress caused by the high-frequency interference of the rubber pad, which leads to the wear of the rubber pad. The operator has to constantly and frequently replace the rubber pad, which affects production efficiency and increases maintenance costs. The new hot-melt adhesive labeling machine is very clean, does not need protection measures to prevent label debris from clogging the glue supply, (such as guitar strings) high-efficiency production.

Precise tension control system – like the brake system on a machine

The tension of the film is controlled by a linear tension device, and the pneumatic actuator controls the slider installed on the recirculating ball bearing to achieve tension. It is a very precise and sensitive system that maintains constant tension throughout the entire range of displacement, even with very thin, small changes in height. Small changes in tension are recorded and immediately transmitted to a servo-motor-controlled dial.

Automatic bottle type conversion….

Labeling of cylindrical containers: ZHEUPACK hot melt adhesive labeling machine is installed with servo motor belt drive to control the rotation of the standard bottle tray on the machine. Bottle type changeover is quick and does not involve slippery pulleys. The entire replacement procedure does not require the use of specific tools.

Quick and easy change of the bottle tray

The bottle tray is quick to remove and install. The entire replacement process can be done without tools.

Bottle conveying device with excellent performance – bottle feeding screw:

The bottle feeding screw is driven by an independent servo motor. Eliminating the bottle-feeding screw of mechanical transmission makes the structure independent and flexible. The labeling machine optimizes the technical parameters of the bottle shape according to the principle of linear logic of up and down flow movement. (cylindrical, square, empty, full…) No need for manual custom solutions. Since the screw is not fixed on the base of the machine, the adjustment between the bottle feeding screw and the center guide plate is synchronous and symmetrical. Adapt the adjusted distance to containers of different diameters. At the same time, the container transmission always moves in the center of the conveyor belt, keeping the synchronous transmission with the bottle-infeed star wheel. When transporting soft, lightweight PET containers, it is critical to keep the containers transported in the center of the conveyor belt, synchronized with the infeed star wheel.

A new generation of bottle conversion parts

The design of the new generation of bottle conversion parts is more durable and lightweight. The overall structure is made of stainless steel. (Different from the traditional plastic bottle conversion parts) the contact part between the conversion part and the container is made of plastic material, which eliminates damage to the container. Replacement is quick and requires no auxiliary tools.

Friendly, easy, and hassle-free operation

The basic structure design of the new generation of hot melt labeling machines is more strategic for the operator. When the safety protection door is opened, the operator can easily approach the standard station at close range, replace the conversion parts, and perform routine maintenance on the equipment. In addition, the operator will easily and conveniently approach the bottle feeding device – the bottle feeding screw, the bottle entering and leaving the star wheel, which is convenient for the operator to change the bottle type. The operation channel of the traditional labeling machine usually causes inconvenience to the replacement and maintenance of equipment configuration. Following the concept of convenient operation and easy maintenance, the new generation of hot melt adhesive labeling machine provides a unique, intelligent and innovative solution to the problem. All RFL-Series labelers come standard with a vertical slide safety guard.

clean hygiene design concept

The most notable design concept of the new generation of hot melt adhesive labeling machines is clean design. All parts are designed in strict accordance with the design concept of cleanliness. Available in a flat or curved design with no holes or grooves to trap dirt. Connections and welded parts are absolutely clean.

Save money on machine maintenance expenses

Important parts of the machine are “visible”. The bottom of the machine, below the worktop, is empty. Visual controls make maintenance easier. Problems are all within sight, and it is easy to take preventive and emergency maintenance when necessary. With the use of brushless servo motors, mechanical parts are reduced by 50%: Fewer mechanical parts = less wear and tear = higher efficiency = lower maintenance costs.

Advanced Solutions

The electrical control cabinet and the labeling machine are integrated into an integral structure. The machine functions and are managed by the motion control system jointly developed by ZHEUPACK and B&R. The technology of B&R Industrial Automation Control Co., Ltd. in Austria A new generation of operation panel, functional touch screen, developed by Italian ZHEUPACK and B&R. Command program for touch screen

And the touch screen page design is designed by “ergonomics and usability” experts to make the machine operation as easy and friendly as possible. The most important thing is to remember that safety is the first in China-Germany – ZHEUPACK has the safety verification and safety guarantee today. The integration of (B&R) B&R’s safety function management system with the motion control system ensures safe operation of the machine in manual or side maintenance mode when the guard system is open.

Qinhuangdao Zhongde Industrial Co., Ltd. is a high-tech machinery company integrating scientific research, design, manufacturing, installation and commissioning, and equipment modification.

The ZD series automatic four-label labeling machine of Zhongde Company is a new product launched by the company. It has formed a production capacity of 20,000 bottles/hour to 60,000 bottles/hour. There are 6 types and 10 models, mainly used for beer and liquor. Labeling of cylindrical containers such as , beverages, etc. The appearance standards of this series of models with four labels are higher than those of similar products. The company’s products are used in Yanjing Beer Group, Tsingtao Brewery Group, China Resources Beer Group, Harbin Beer Group, Zhujiang Beer Group, Chongqing Beer Group, Jinxing Beer Group, Xinjiang Beer Group, Golden Lion Beer Group, Asia Beer Group and other enterprises.